Widespread AI adoption is rapidly changing the workforce, and the manufacturing industry is no exception.

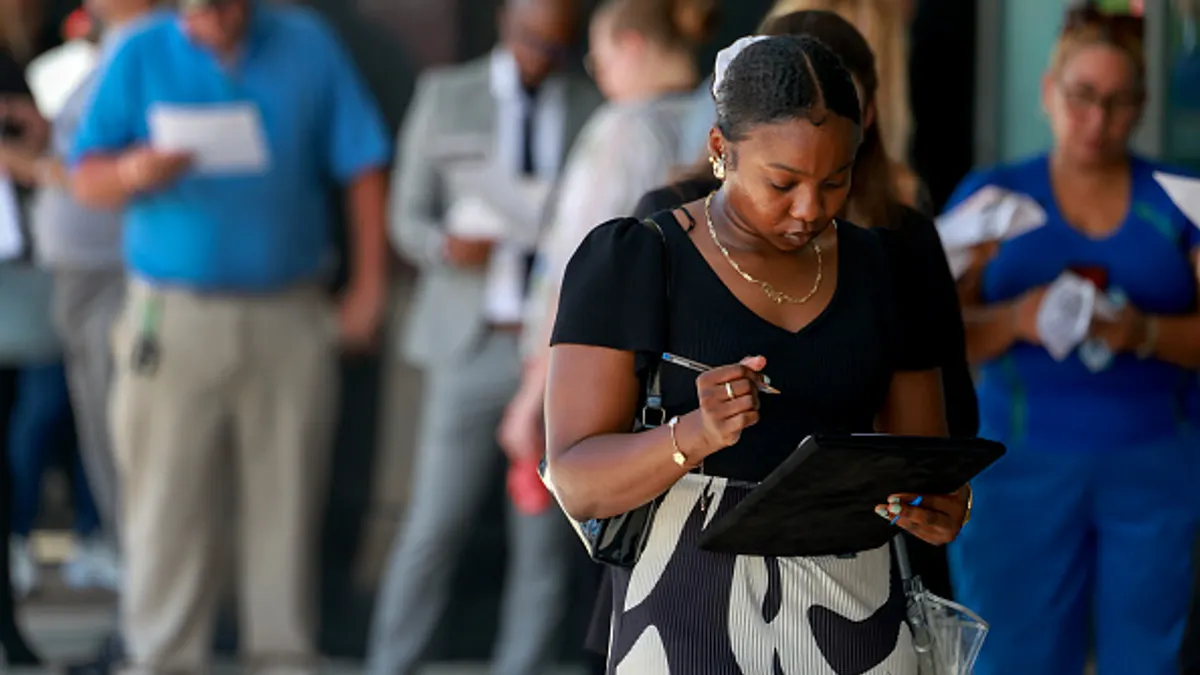

These changes have sparked anxiety in many workers. More than four in 10 frontline workers fear AI technologies could replace their job in the next decade, according to a June 2024 Boston Consulting Group survey.

Generative AI is expected to significantly change half of all jobs, according to research by Cognizant and Oxford Economics. As a result, 9% of the current U.S. workforce could be displaced.

Such displacement fears could also cause more workers to leave their posts. A 2023 Gartner survey found that workers who fear AI will replace their jobs are 27% less likely to stay with their employer, potentially exacerbating the manufacturing workforce shortage.

To avoid such concerns and ease worker anxiety, manufacturers integrating AI are taking proactive steps to ensure the rollout of the tech doesn’t significantly disrupt existing workflows so productivity is enhanced, not replaced, by AI.

Involving workers in the process

A key strategy in rolling out AI is involving workers in the process from the outset.

“When workers feel they have a say in adopting new technology, they tend to engage more positively,” said Kate Field, global head of human and social sustainability at BSI. “Conversely, if it feels ‘forced’ on them, they may be more resistant.”

Freudenberg, a manufacturer of household, automotive and other products, has involved its team early in tech integration through tasks such as data collection and consultations to eliminate uncertainties and give workers a sense of ownership in the process, said Vishwanath Hegadekatte, senior manager of future technologies at Freudenberg North America.

“It is about keeping them in the loop from the beginning so they know what to expect and how it will improve their work environment,” Hegadekatte said. “People need to feel comfortable and confident with the technology if it is to work effectively.”

SmartSKN, a personalized skincare manufacturer, found it easier to implement this from day one as its entire production model is AI-based.

“Our employees were hired specifically to operate AI robots, so there was no anxiety about being replaced by AI,” said Val Neicu, CEO of SmartSKN. “Our human employees and AI robots now work together as a cohesive team — the humans even named the robots and count them as part of the floor team.”

Training is vital to success

However, not all manufacturers have been AI-focused from the start, so many experience a learning curve while adopting new technology and upskilling workers to use it effectively. This training period can make or break successful AI adoption.

“Providing effective training is crucial — not just an initial session, but ongoing Q&A and refreshers,” said Field from BSI. “Designating some workers as ‘champions’ of the new technology, with additional training, can also be highly effective."

Freudenberg takes this a step further by offering workers an inner look into just how the AI works.

“We’re demonstrating what systems we’re using, what software is being implemented and really giving them that insight into the back end so AI isn’t a scary unknown,” Hegadekatte said.

The company uses both external AI tools like the Microsoft CoPilot and internally developed AI models specifically tailored to address unique challenges at Freudenberg. These internal tools can be particularly crucial, as external resources to learn may not be available considering the proprietary nature of the software, Hegadekatte added.

Along with ongoing training, maintaining open communication throughout the process can ensure a smooth transition.

“Communication is key, we’ve found,” Hegadekatte said. “We have direct conversations with employees to let them know our exact intention for using AI (optimizing processes) and how we plan on using it. We involve them in the process, so these changes are coming slowly and with their full knowledge.”

SmartSKN also prioritizes transparency and communication when introducing AI.

“Creating an open environment where team members can ask questions and provide feedback helps ease concerns and encourages adoption,” Neicu said.

Tackling persistent fears

Still, sudden change can overwhelm factory workers already fearing AI replacement. To ease the transition, many manufacturers should adopt AI gradually, one process at a time, ensuring both decision-makers and workers feel confident in the new workflow, said Praveen Rao, global head of manufacturing solutions at Google Cloud, which offers AI-driven manufacturing software solutions.

“Choosing technologies that integrate with existing systems and workflows reduces friction, while providing ongoing support and resources empowers employees to troubleshoot issues and optimize their use of the new tools,” Rao said.

Companies should then begin with a small-scale pilot to demonstrate value and gather feedback prior to a full rollout, Rao added.

Ultimately, it is an employer’s responsibility to ensure workers understand AI should help enhance their job, not replace it.

“Most anxiety comes from the fact employees fear AI will displace their job but we are very transparent that AI is not meant to replace our workforce," Hegadekatte said. "Rather, AI is a resource that can help us do our jobs more efficiently.”